Cyanide Hardening of Clutch Plates Central Process

at Automotive Products

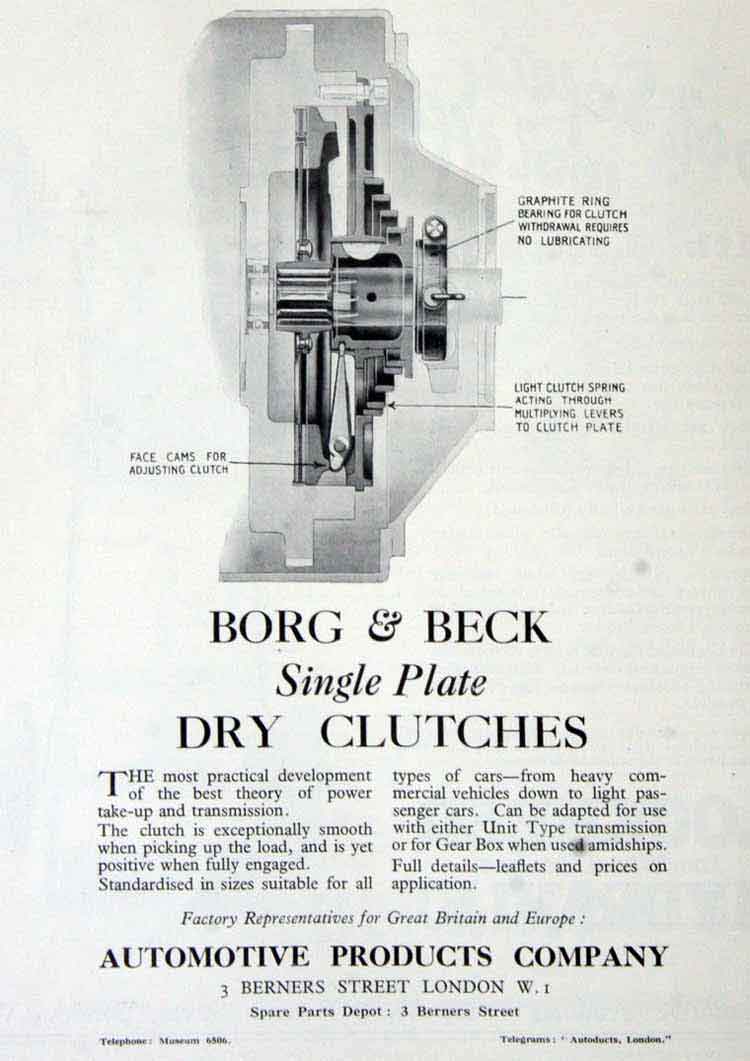

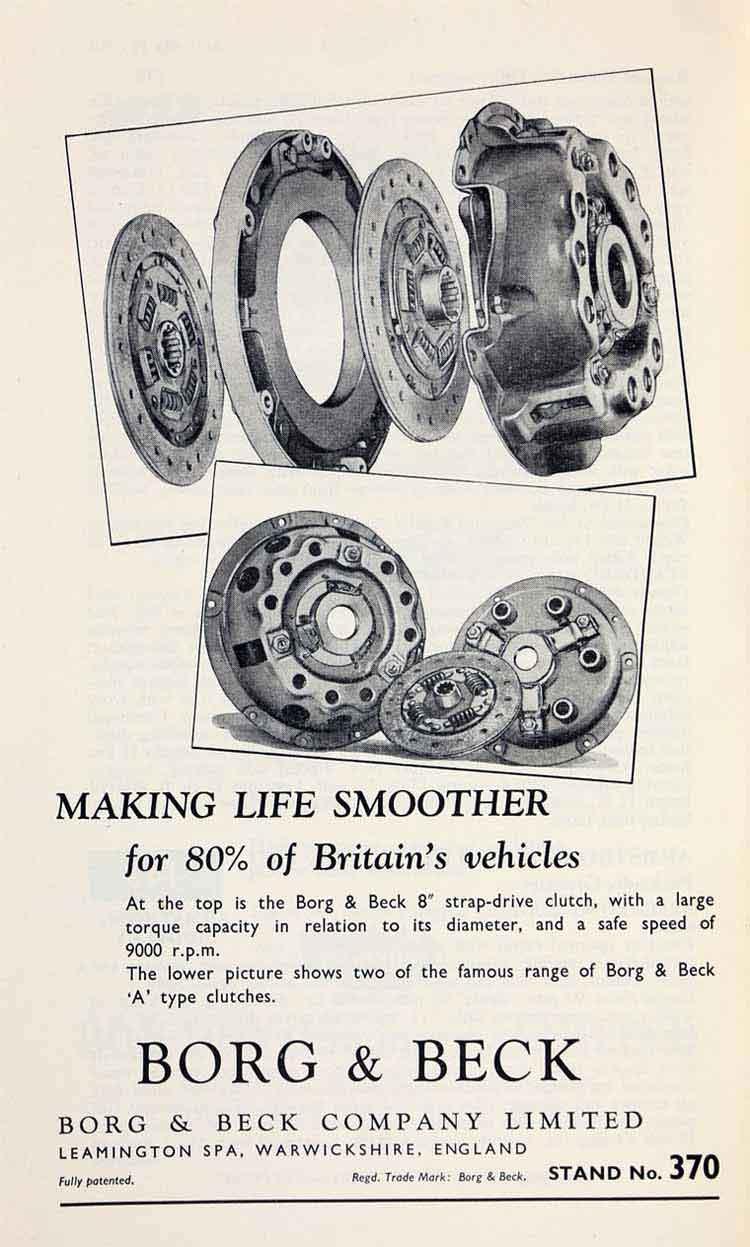

Automotive Products of Tachbrook Road, Leamington Spa were designers and manufacturers of various automotive parts. These included Lockheed Hydraulic Brakes, Borg and Beck Clutches, Thomsom Tie rods and AP Automatic Gearboxes.

Most of the metal heat treatment and finishing operations on components were concentrated in a division located in the centre of the factory called Central Process. This had a workforce totalling around 250 and consisted of many furnaces, electroplating, surface finishing and painting plants. One furnace process which has generally become extinct at the end of the twentieth century due to ecological and safety issues is cyanide hardening.

The centre plates of the Driven Clutch plate are pressed out of a low carbon steel (Mild Steel) and are known as the adaptor and retainer plates. The adaptor plate acts as the anchor for the clutch linings and the retainer plate holds the hysteresis springs, hub and friction washers in position.

These plates have an arduous task and are subjected to high stresses and wear forces especially around the spring windows. The steel used for the pressing is in a very soft state so that the plate can be easily and accurately pressed out. If they were used in this state the clutch plate would be rattling after less than 1000 miles. To prevent this, plates are case hardened to a depth of around 0.15mm (0.006”). This increases the surface harness around 9 times. (80 HV2 to 700HV2) and the plate stiffness.

Case hardening involves the diffusion of carbon and nitrogen into the surface of the steel and then the subsequent quenching into a suitable media to harden the surface.

One method for this which was developed at the start of the twentieth century is cyanide hardening. Cyanide hardening involves the immersion of the parts in a molten mixture of salts at temperatures over 800oC. A typical salt mixture is 20% Sodium Cyanide, 50% Sodium Carbonate and 30% Sodium Chloride. Sodium Cyanide NaCN which is the active ingredient is an unstable compound and breaks down in the presence of oxygen to release nascent carbon and nitrogen atoms which diffuse into surface of the steel.

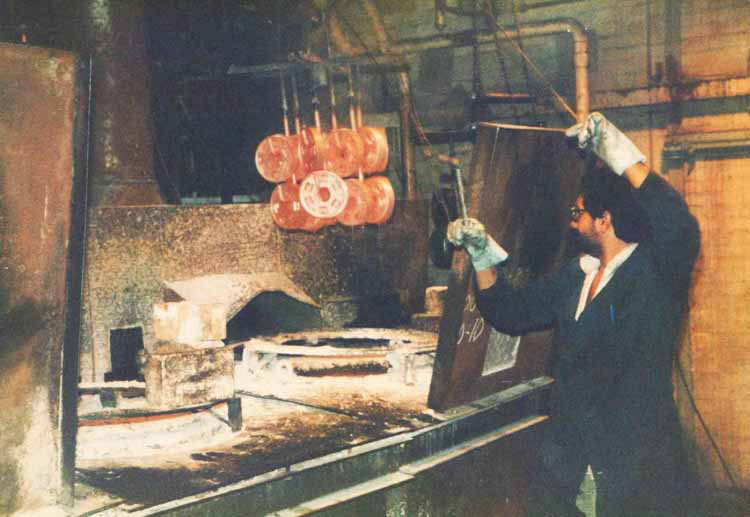

The Clutch plates were hung vertically on steel Jigs and preheated to around 200ocC to dry them and burn off any pressing oil. Any dampness remaining on the plates reacts violently with molten cyanide which can spatter hot cyanide salt over everyone and everything in the vicinity.

The plates were immersed for 40 minutes in the cyanide and then lifted out and quickly lowered into a thin mineral oil to quench them to room temperature. The maximum time from molten salt to quench oil being 7 seconds. The cyanide deposit was washed off with water and then the plates then went on to be phosphated and oiled with linseed oil based preservative oil.

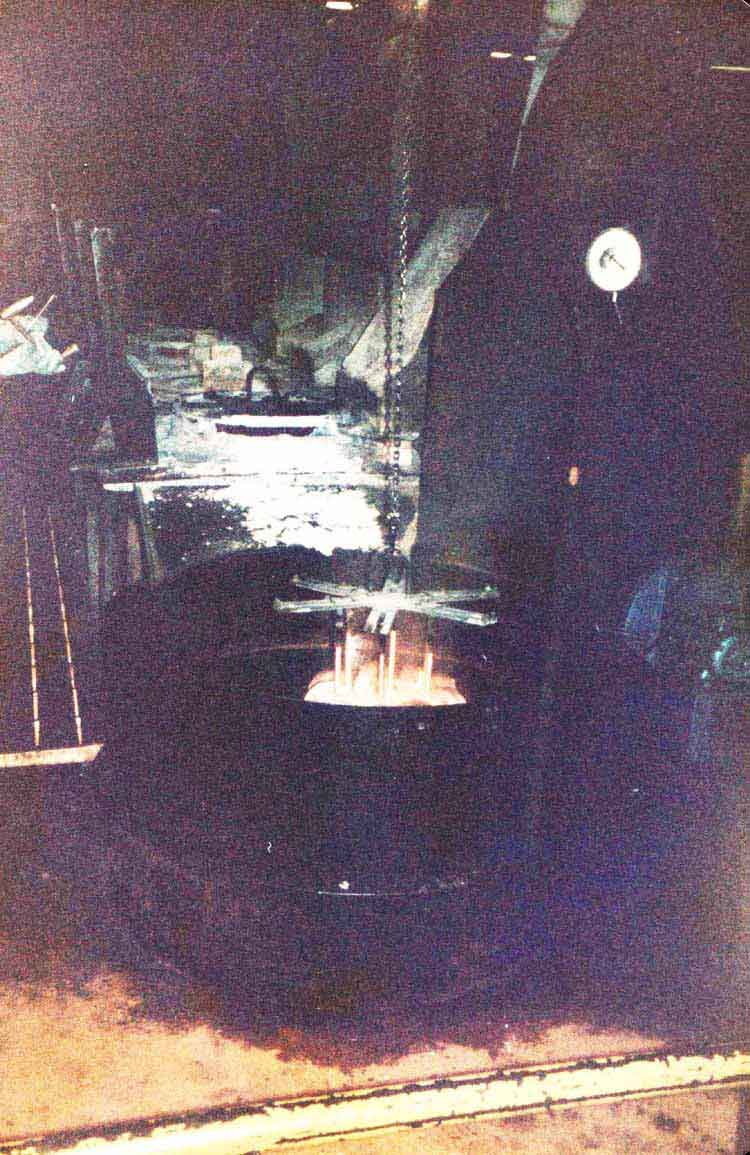

The section in Central Process which carried out this process was called the Borglite Section as this was the original name of the design of the clutch. It consisted of 6 Cyanide pots which were 2 foot diameter and 2 foot depth and made of heat resisting steel. Adjacent to each cyanide pot were 6 empty pots which were used to pre-heat the loads. The pots were held in a box type furnace which was fired with gas. The tops were open and had some steel screens and grills in front to give the operators some protection and extraction was fitted to remove fumes.

The section was run for 24 hours a day, 7 days a week and 51 weeks per year. Each 8 hour shift was manned by 3 operators, and there were 4 groups of 3 operators. A working week was 42 hours. Holidays and illness were covered by overtime.

Control of the process was by measuring the case depth and surface hardness of the clutch plates from samples taken every 2 hours from each pot. Results were plotted on to an SPC chart. Also the strength of the cyanide in each pot was measured daily by titration. Samples for titration were taken by dipping a steel rod in the molten cyanide and then breaking off the solidified salt flakes, crushing with a pestle and mortar, then weighing out 1 gram and dissolving in water. A normal Nickel Ammonium Sulphate Solution was used for the titration with Dimethylglyoxime as the indicator.

Additions of cyanide salt were made into the pots every shift to replace drag out. The operators were on group bonus and each operator was expected to produce 22 loads per shift using 2 of the pots. Most of the operators were of Asian descent.

Safety was an issue but apart from the odd small burns there were no accidents. Personal protection was limited to Safety Glasses (optional) and overalls. Eating and drinking on the section was prohibited. Cyanide poisoning antidote was available on the section but was never used, (Its effectiveness was always in doubt).

The cyanide was supplied by ICI/Degussa and came in the form of pellets packed into sealed steel drums. The factory safety officer always insisted that the cyanide store on the section was kept locked. This was queried on occasions as there were large amounts of cyanide all over the section. The answer was that he could not do anything about that but he could insist that the store was locked!

Several million Clutch plates were hardened every year and the usage of the cyanide salt was in tons per week. Cyanide waste was quite substantial from two sources. The 15 foot deep oil quench tanks filled up quite quickly with dragged out salt. Pots found to be weak in cyanide strength had some molten salt bailed out into steel drums to make way for fresh cyanide additions.

The disposal of the cyanide waste was a controversial issue. The old official way of disposing was the dumping of it out at sea at least 100 miles from the coast by ICI. The cyanide was packed into the original steel drums.

When this was stopped in the 1970’s other dubious contractors took over the disposal. Incidents of drums of cyanide waste dumped in road lay-bys brought in government action for the licensing of the safe disposal of cyanide waste.

Cyanide Hardening was the favoured method of case hardening clutch plates as it produced less distortion of the plates and subsequently low clutch judder in use.

The flatness tolerance on most of the plates was 0.020” but this was rarely achieved and a concession for flatness of 0.050” was regularly issued.

Distortion of the plates to above the 0.020” limit was due to a combination of effects which included Internal Stresses in the original pressing, heating and quenching stresses. Attempts were made to improve the flatness by the installation of an Induction re-heating and press quenching process. This was only partially successful and tended to result in flat plates but with out of position holes.

Another major problem came in the late 70’s when the pressing suppliers (AP Pressings) took it on themselves to change the material to an extra deep drawing steel strip. This made the pressing easier but the high aluminium and low residual elements in the steel interfered with the cyaniding process, surface hardness and case depths were below specification. Lower surface hardness’s were concessed but unfortunately that was not enough and nearly 100 tons of Pressed Plates were scrapped. A system of material approval and trials then had to be established for each new cast used by the Pressings company.

Further developments in using sealed quench gas atmosphere furnaces to case harden and produce low distortion were eventually developed and replaced this process. The cases produced in the sealed quench furnaces were stronger than cyanide and steels with higher aluminium contents could be successfully treated.

The section was decommissioned and decontaminated in the early 1990’s.

Copyright © Stuart Robertson 23rd April 2020